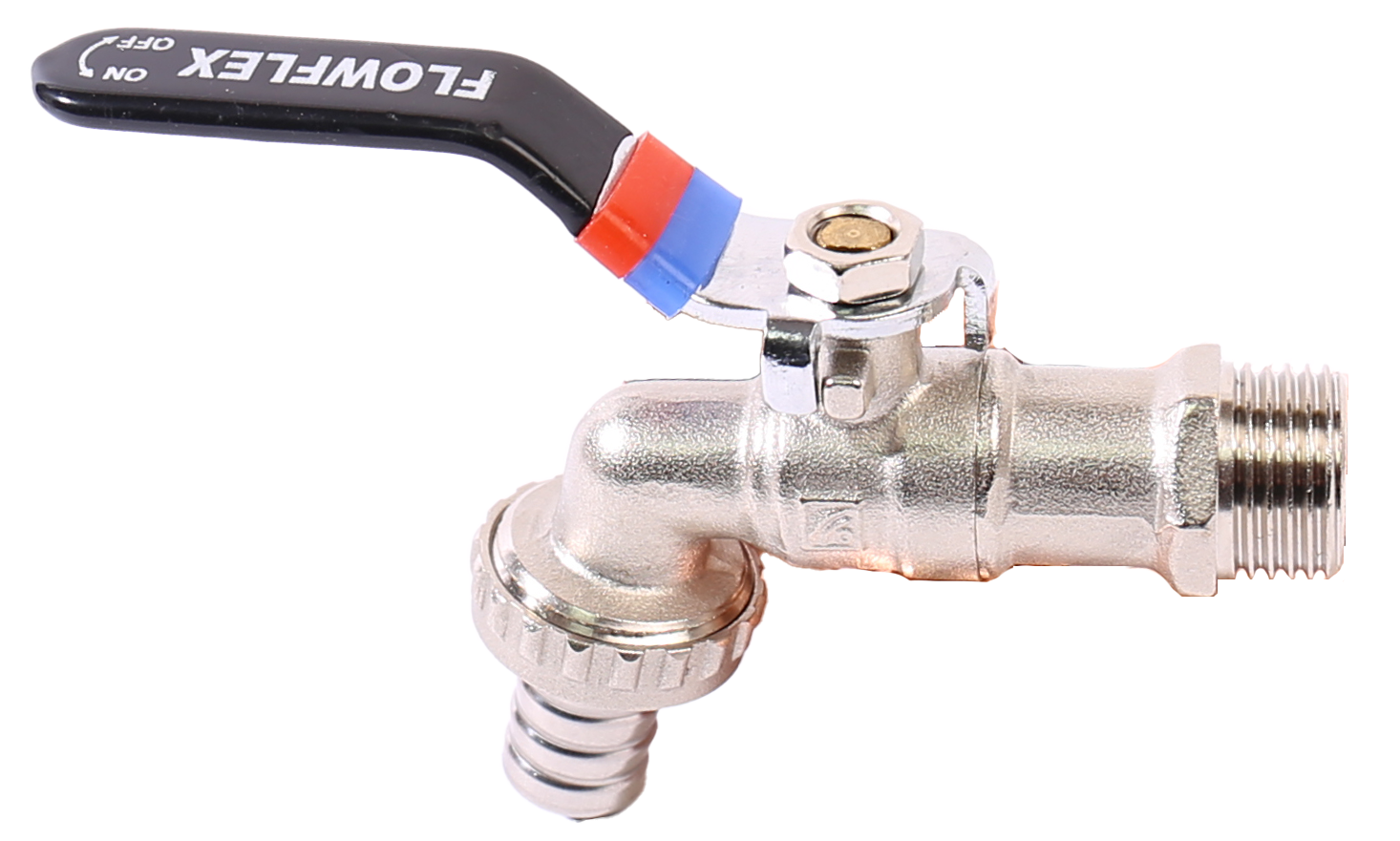

Flowflex Hose Union Ball Type Bib Taps are a quick way of distributing and shutting off flow in a system. Flow is controlled through a quarter turn action which moves the hole in the ball inline or out of line with the flow, preventing or facilitating flow as appropriate. Chrome finish for an aesthetically appealing design.

Applications

- Domestic

- Commercial

- Industrial